In my opinion, a heritage masonry restoration project should be done in a viable way for the benefit of the structure; but purism is out of reach, unless one has really deep pockets and is being sentimentally inclined.

I’ve once met a man who, having reportedly just spent $920,000 to fix the inside of his house, told me: “When it comes to the outside, I get the restoration boys to do it my way”. And the eventual result was plain awful.

The type of heritage project result that is many notches up the purity scale is usually only done on serious landmark buildings, as it generally costs in the six figures for a building of comparative size to a residential home. And even then, there always seems to be some compromise, one way or the other, in the end.

Over a decade ago, I was pushing to sell such spec in earnest, but *never* had a taker. No one, in the residential arena is willing to push it that far. I’ve actually had several wealthy — two of them prominent — individuals tell me that all they wanted was a reasonable, minimally viable standard, to paraphrase them. And I was told that the money otherwise would rather be donated away to charity before spending it to “that” degree on restoring that particular individual’s house.

The type of heritage project result that is many notches up the purity scale is usually only done on serious landmark buildings, as it generally costs in the six figures for a building of comparative size to a residential home. And even then, there always seems to be some compromise, one way or the other, in the end.

Over a decade ago, I was pushing to sell such spec in earnest, but *never* had a taker. No one, in the residential arena is willing to push it that far. I’ve actually had several wealthy — two of them prominent — individuals tell me that all they wanted was a reasonable, minimally viable standard, to paraphrase them. And I was told that the money otherwise would rather be donated away to charity before spending it to “that” degree on restoring that particular individual’s house.

Such spec would require an advanced mortar analysis to be conducted in a lab at a cost ranging from $2,000 to $3,500 to get instrumental testing done, such as polarized light/thin-section microscopy, scanning electron microscopy, atomic absorption spectroscopy, X-ray diffraction, differential thermal analysis, and more.

Following that would be an extensive research to source out, from various material libraries across North America, and re-create the exact sand, and precisely determine what the binder needs to consist of and what the additives actually need to be. This step alone is very time-consuming, and therefore expensive.

Each type of sand would have required a minimum investment of $5,000 at the time, to import into Canada, plus storage costs of $200/month. And it still would not have been a perfect match, at least in the majority of the projects.

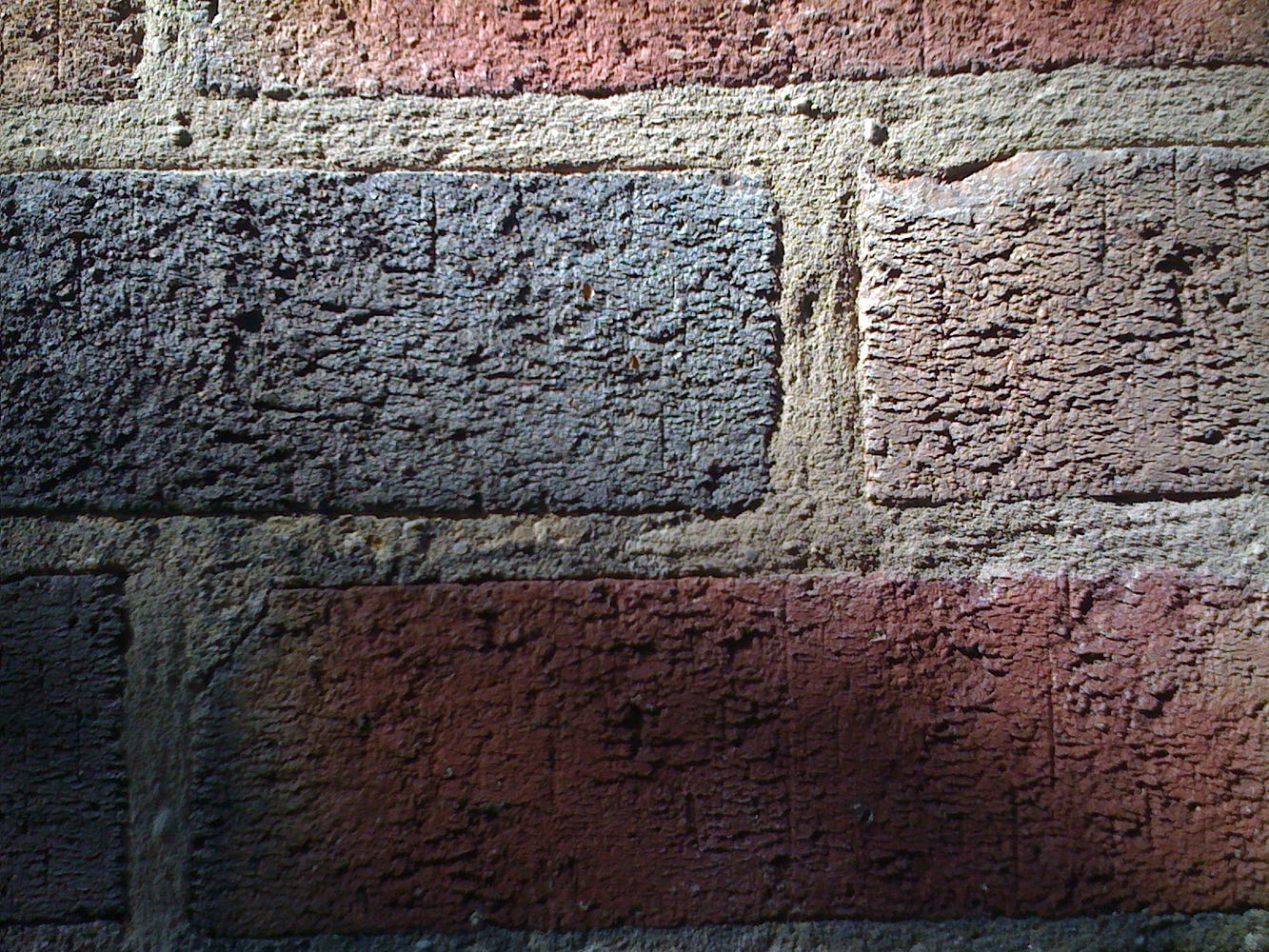

In the case of my company, Invisible Tuckpointing Ltd., which performs repointing services (also known as tuck pointing), as well as brickwork / stonework restoration, customers, including Toronto Preservation Services are more than satisfied with a “close enough” approximation as I’m doing by a “mix and match” approach of various locally available sands, based on a simple mortar analysis, generally conducted by crushing a sample taken from of the house and even dissolving it in acid. And everyone I know in the restoration field uses sands exactly as I am using, and mixes and matches them as best as can be done so as to approximate the in situ mortar — if they bother at all. The following picture features one of my matches, wherein some of the mortar is original, and some we’ve replaced. Can you tell them apart?

Furthermore, the lime (calcium hydroxide) would need to be prepared by acquiring quicklime (calcium oxide), a material now classified as hazardous, and slaking it (adding water to the quicklime so as to create an exothermic reaction) by concurrently adding sand along with the water so as to create a “hot mix” which is what would introduce little chunks of of unslaked lime, similar to those most likely found in the existing mortar on your house. This would require a substantial amount of testing and sieving, and retesting so as to achieve just the right ratio of lime chunks. In other words, simply using lime in the form of a bagged, ready-to-use product (even if its benefits as a hydraulic lime are being highly praised) would not be a puristic way to proceed.

Personally, I’m an advocate of aiming for an aesthetically pleasing restoration of vintage brick or stone buildings using compatible materials, with the goal to blend the repairs so well, they become invisible; while making sure the process used will not damage, ruin or deface the original masonry assembly.

The reason why I do masonry, speaking for myself, of course, is to make it into a form of art. At my company, our skillset lays in reversing the unwanted effects of time — or of previously poorly performed repairs — on the masonry building envelopes of older structures.

And while we’re at it, we also aim at creating as-near-perfect-as-possible, glitch-free experiences with our clients so as to have elated customers as a result.

Based on my observations, that approach seems more valuable to consumers than purism pursued for its own sake.

Toronto residents: www.invisibletuckpointing.com

For anyone else: www.brickworkpreservation.com

Positive site, where did u come up with the information on this posting?I have read a few of the articles on your website now, and I really like your style. Thanks a million and please keep up the effective work. Anna

ReplyDelete